The first thing required for the development of structural framework of the building by design and construction professionals, are structural drawings. For the actual development of structural framework of the building, engineering solutions such as structural steel detailing structural drafting services, precast detailing, rebar detailing, and structural design services such as structural modeling and analysis are enormously essential. When it comes to the development of highly strong structure, structural detailing & drafting are the prime necessities.

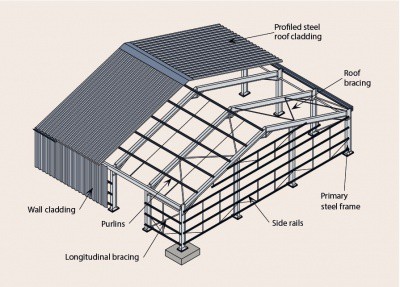

During preconstruction, many different types of Structural Drawings are created by construction & design professionals which comprise structural shop/fabrication drawings, chimney drawings, structural connection drawings & erection drawings etc. Throughout the structural drafting process, all these drawings are generated by trained drafters with the close collaboration of structural engineers who keep on directing them. Other technical and highly important drawings which are also made during structural drafting contain roof, truss & joint drawings & foundation plan drawings etc. When it comes to the design & construction of structural framework, the role of structural drafters and detailers cannot be overlooked by engineers, architects, fabricators and contractors etc. They are solely answerable for the detailed development of fabrication drawings, erection drawings detailed technical plans and reports etc., when it comes to the importance of structural detailers.

All types of structural drawings, whether developed by detailers or drafters, must be revised, observed and approved by structural engineers before they are finally optimized by design and construction professionals for the actual development of structural framework.

Fabrication drawings and erection drawings must be made with extreme accuracy among all the above mentioned structural drawings, since they are optimized by design and construction professionals for extremely severe purposes which consist of manufacturing of structural parts & their eventual installation. Quality of those drawings can never ever be negotiated which are utilized by fabricators for manufacturing steel components as it can disturb the entire project very harmfully. Hence drawings formed for the optimization of manufacturers and steel erectors must be studied with high attention by structural services engineers so that no difficulties are confronted by them.

Visit Us: StrucCore