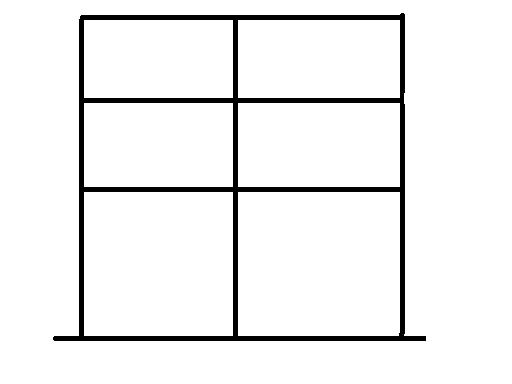

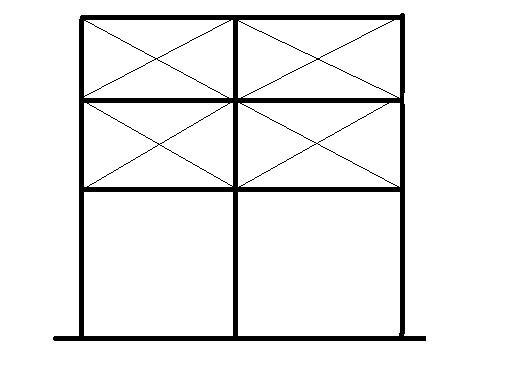

Precast concrete is a construction product generated by casting concrete in a reusable mold or “form” which is then treated in a controlled environment, conveyed to the construction site & lifted into place. Whereas, standard concrete is decanted into site-specific forms & cured on site.

By generating precast concrete in a controlled environment (typically called as a precast plant), the precast concrete has the prospects of being properly cure and be carefully monitored by plant staffs. A precast concrete system has many advantages over onsite casting. Precast concrete production is carried out on ground level, which also helps with safety throughout a project. There is better hold over material quality & workmanship in a precast plant compared to a construction site. The forms used in a precast plant can be reused hundreds to thousands of times before they have to be replaced, when looking at the cost per unit of formwork; it often makes it cheaper than onsite casting.

Advantages:

- Good quality control

- Very rapid speed of erection

- Rapid construction on site

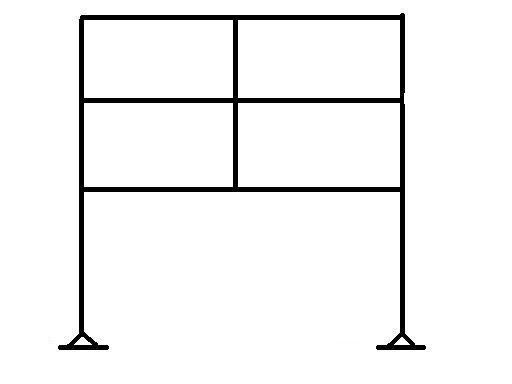

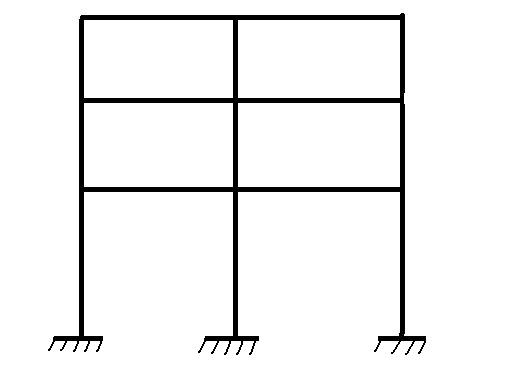

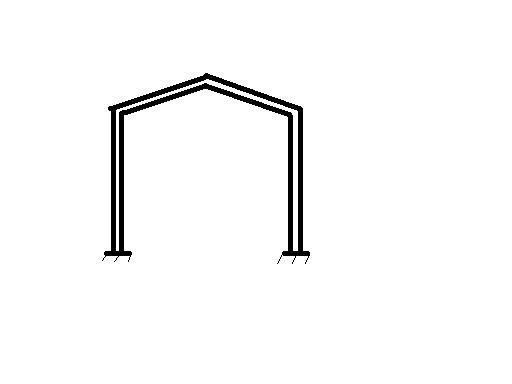

- Entire building can be precast-walls, floors, beams, etc.

- Pre-stressing is easily done which can reduce the size and number of the structural members.

- High quality because of the controlled conditions in the factory

Disadvantages:

- Camber in beams and slabs

- Very heavy members

- Connections may be difficult

- Very small margin for error

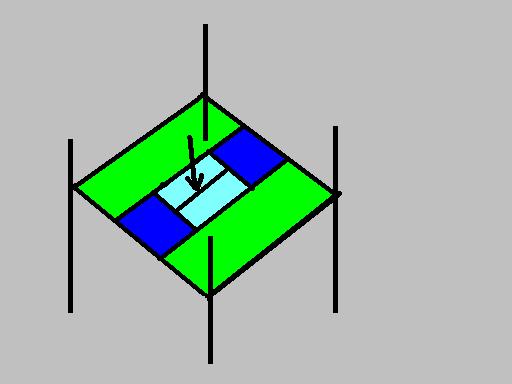

- Because panel size is limited, precast concrete cannot be used for two-way structural systems.

- Somewhat limited building design flexibility

- Need for repetition of forms affects building design.

- Joints between panels are often expensive and complicated.

- Economics of scale demand regularly shaped buildings.

- Cranes are required to lift panels.

- Skilled workmanship is needed in the application of the panel on site.